Project Description

Lithium Iron Phosphate Battery power wall 51.2V/50Ah/100Ah/200Ah

Lithium Iron Phosphate Battery power wall 51.2V/50Ah/100Ah/200Ah

- 4000 cycles @80% DoD for an effectively lower total of ownership cost;

- Low maintenance batteries with stable chemistry;

- Battery Management

| ELECTRICAL PERFORMANCE | |||

| Model Num | 51.2V/50Ah | 51.2V/100Ah | 51.2V/200Ah |

| Nominal Voltage | 51.2 V | 51.2 V | 51.2 V |

| Nominal Capacity | 50Ah | 100 Ah | 200 Ah |

| Capacity @ 20A | 150 min | 300 min | 600 min |

| Energy | 2560 Wh | 5120 Wh | 10240 Wh |

| Communication | CAN2.0/RS232/RS485 | CAN2.0/RS232/RS485 | CAN2.0/RS232/RS485 |

| Resistance | ≤45 mΩ @ 50% SOC | ≤45 mΩ @ 50% SOC | ≤45 mΩ @ 50% SOC |

| Efficiency | >96% | >96% | >96% |

| Module Parallel | Up to 3 packs | Up to 3 packs | Up to 3 packs |

| CHARGE PERFORMANCE | |||

| Recommended Charge Current | 20A | 20A | 20A |

| Maximum Charge Current | 50A | 100A | 100A |

| Recommended Charge Voltage | 57.6V | 57.6V | 57.6V |

| BMS Charge Cut-Off Voltage | <58.4 V (3.65V/Cell) | <58.4 V (3.65V/Cell) | <58.4 V (3.65V/Cell) |

| Reconnect Voltage | >57.6 V (3.6V/Cell) | >57.6 V (3.6V/Cell) | >57.6 V (3.6V/Cell) |

| Balancing Voltage | <57.6 V (3.6V/Cell) | <57.6 V (3.6V/Cell) | <57.6 V (3.6V/Cell) |

| Maximum Batteries in Series | 16 (*Consult MUST) | 16 (*Consult MUST) | 16 (*Consult MUST) |

| DISCHARGE PERFORMANCE | |||

| Maximum Continuous Discharge Current | 50 A | 100 A | 100 A |

| Peak Discharge Current | 60 A (3s) | 110 A (3s) | 110 A (3s) |

| BMS Discharge Cut-Off Current | 75 A (300ms) | 150 A (300ms) | 150 A (300ms) |

| Balancing open voltage | 55.2 V (3.45V/Cell) | 55.2 V (3.45V/Cell) | 55.2 V (3.45V/Cell) |

| Recommended Low Voltage Disconnect | 44 V (2.75V/Cell) | 44 V (2.75V/Cell) | 44 V (2.75V/Cell) |

| BMS Discharge Cut-Off Voltage | >32.0V (2s) (2.0V/Cell) | >32.0V (2s) (2.0V/Cell) | >32.0V (2s) (2.0V/Cell) |

| Reconnect Voltage | >40.0 V (2.5V/Cell) | >40.0 V (2.5V/Cell) | >40.0 V (2.5V/Cell) |

| Short Circuit Protection | 250 ~ 500 μs | 250 ~ 500 μs | 250 ~ 500 μs |

| COMPLIANCE | |||

| Certifications | CE (battery) UN38.3 (battery) UL1642 & IEC62133 (cells) |

CE (battery) UN38.3 (battery) UL1642 & IEC62133 (cells) |

CE (battery) UN38.3 (battery) UL1642 & IEC62133 (cells) |

| Shipping Classification | UN 3480, CLASS 9 | UN 3480, CLASS 9 | UN 3480, CLASS 9 |

| MECHANICAL PERFORMANCE | |||

| Dimension (L x W x H) | 525 x 350 x 135 mm 20.7 x 13.8 x 5.3″ |

580 x 400 x 145 mm 22.8 x 15.7 x 5.7″ |

580 x 420 x 230 mm 21.7 x 16.5 x 9.05″ |

| Approx. Weight | 10.5 lbs (23 kg) | 20.0 lbs (44 kg) | 37.2 lbs (82 kg) |

| Terminal Type | DIN POST | DIN POST | DIN POST |

| Terminal Torque | 80 ~ 100 in-lbs (9 ~ 11 N-m) | 80 ~ 100 in-lbs (9 ~ 11 N-m) | 80 ~ 100 in-lbs (9 ~ 11 N-m) |

| Case Material | SPPC | SPPC | SPPC |

| Enclosure Protection | IP65 | IP65 | IP65 |

| TEMPERATURE PERFORMANCE | |||

| Discharge Temperature | -4 ~ 131 ºF (-20 ~ 55 ºC) | -4 ~ 131 ºF (-20 ~ 55 ºC) | -4 ~ 131 ºF (-20 ~ 55 ºC) |

| Charge Temperature | -4 ~ 113 ºF (0 ~ 45 ºC) | -4 ~ 113 ºF (0 ~ 45 ºC) | -4 ~ 113 ºF (0 ~ 45 ºC) |

| Storage Temperature | 23 ~ 95 ºF (-5 ~ 35 ºC) | 23 ~ 95 ºF (-5 ~ 35 ºC) | 23 ~ 95 ºF (-5 ~ 35 ºC) |

| BMS High Temperature Cut-Off | 149 ºF (65 ºC) | 149 ºF (65 ºC) | 149 ºF (65 ºC) |

| Reconnect Temperature | 131 ºF (55 ºC) | 131 ºF (55 ºC) | 131 ºF (55 ºC) |

| HEATING FOIL PERFORMANCE | |||

| Heating Temperature Range | -4 to 41 ºF (-20 to 5 ºC) | -4 to 41 ºF (-20 to 5 ºC) | -4 to 41 ºF (-20 to 5 ºC) |

| Heating Time | Approximately 1 hour @ 7.5 A | Approximately 1 hour @ 7.5 A | Approximately 1 hour @ 7.5 A |

| BMS Heating Foil Cut-Off | 158 ºF (70 ºC) | 158 ºF (70 ºC) | 158 ºF (70 ºC) |

- 4000 Cycles @80% DoD For Effectively Lower Total Of Ownership Cost;

- Low maintenance batteries with stable chemistry;

- Battery Management System (BMS) is incorporated against abuse;

- Up to 6 months thanks to its extremely low self-discharge (LSD) rate and no risk of sulphation;

- Save time and increase productivity with fewer downtime thanks to superior charge/discharge efficiency;

- Suitable for use in a wider range of applications where the ambient temperature is unusually high: up to +60°C;

- Lithium batteries provide more Wh/Kg while also being up to 1/3 the weight of its SLA equivalent.

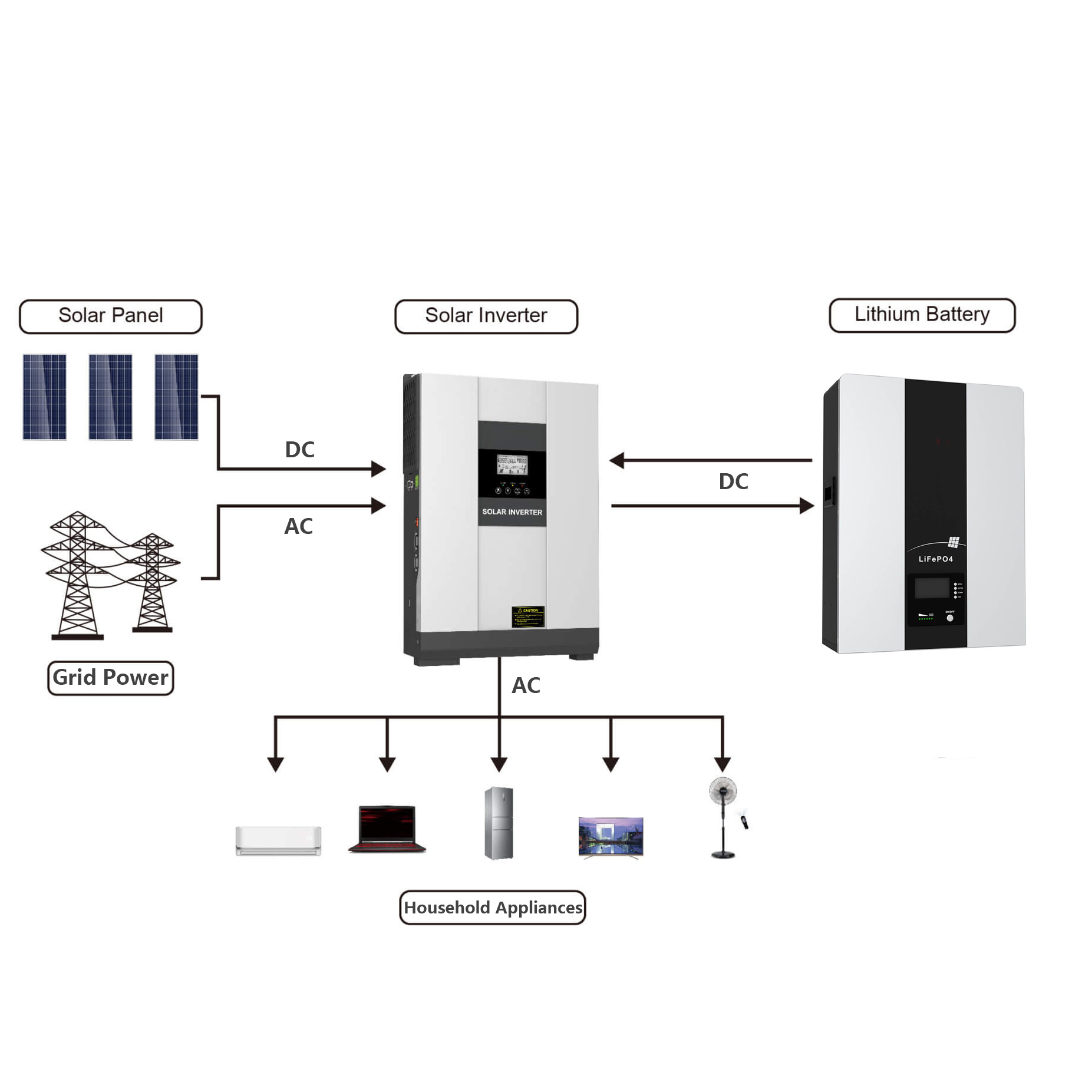

APPLICATION:

Lithium Iron Phosphate can be used in most applications that use Lead Acid, GEL or AGM type batteries.

Suitable applications include:

- Solar Storage

- Switching applications and more

- Base transceiver station

- Communication equipment

- Central office

- Telecommunication systems

- Electronic cash registers

- Microprocessor-based office machine

- UPS